Sometimes life gets busy. Or maybe it’s always busy for some of you. And maybe the last thing you end up thinking about is your pond or lake aeration system. A lack of aeration maintenance is one of the most common causes of fish kills, both in summer and winter.

All piston compressors and diaphragm air pumps require periodic maintenance to keep their output up, and to allow for a useful lifespan. Procrastinating on this maintenance can result in reduced water quality, a drop in oxygen, fish kills, and premature equipment failure. This is the case for AC electric compressors, DC solar compressors, diaphragm and linear air pumps, and even windmills.

What is involved in performing maintenance on your aeration system?

-

some basic cleanup,

-

some quick air filter maintenance, and

-

installing a rebuild kit every 1-3 years which typically takes an hour or less.

Here is what we recommend:

Clean out your cabinet or compressor area

At least once per year, we recommend cleaning out your compressor or air pump box (vacuumed, or blown out with compressed air) to remove dust or debris, dead insects, fallen leaves etc from around the compressor. This will allow for proper cooling, will limit air filter plugging, and will improve the life of your aeration system

Clean or replace the intake air filter as needed

All compressors and air pumps should have an intake air filter to limit the intake of dust or debris inside. This usually is a black metal or plastic pod sticking off the side of the compressor head, you can twist the cap off to reveal the pleated or felt air filter element. This should be checked and cleaned or replaced as needed (this may be as often as every few weeks, or as long as every few months during the spring/summer/fall seasons depending on the operating conditions). Typically in winter there is not much dust, debris or insects unless you are running your compressor inside a building. A plugged filter will cause the compressor to run hotter, will shorten the lifespan and will draw more electricity as the motor needs to

work harder. We have new filter canisters and filter elements in stock.

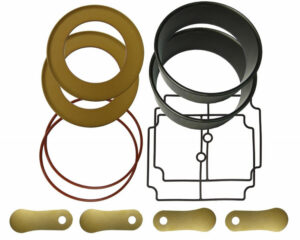

Replace the ‘wearable’ parts on your compressor or air pump maintenance kit. All aeration compressors and air pumps have wearable parts. With compressors this would include cylinder sleeves and piston seal cups, along with flapper valves and o-rings. Diaphragm pumps would include the rubber diaphragm, spring or flapper valves, and sometimes o-rings. A linear air pump would have diaphragm cartridges, and sometimes replacement magnets. Some Solar DC compressors also require the motor brushes to be replaced if it is not a brushless motor. Worn parts cause reduced air flow which limits the oxygen going to the pond and greatly reduced the cooling ability of the system. Especially in the summer months, an excessively hot system will wear out quickly.

We carry rebuild kits in stock for the most common aeration compressors and air pumps on the market. Please have a model number or picture of your compressor prior to contacting us to order. If you purchased the system from us, we should be able to look it up in our system if it was in the last 5-6 years.

Longer Cycle Maintenance

Replace the cooling fan. Typically, cooling fans can last 4-6 years or more. Sometimes they don’t if the cabinet intake/outlets are plugged with leaves or tall grass, or it’s a very hot/dusty environment. If your fan fails, the compressor life will be shortened considerably. If you don’t have a fan in an enclosure with your piston compressor, you should add one. We also have fan cooled shelves/bases if your compressor is mounted in an existing building or shed, this added cooling can extend time between rebuilds and lengthen the life of the compressor. We have some fans in stock, some are special order if they are for larger systems or irregular voltages. Please contact us to find out if we have what you need.

Pressure Valves and Gauges

Some of the important fixed components in your aeration system may wear out over time and need replaced. Two items that are relatively common to replace over several years are the pressure gauge and the pressure release valve. Heat and vibration can cause these components to fail. When we rebuild compressors for customers, we always check these and replace as needed.

A pressure release valve protects your compressor in case of freeze up conditions, or a pinched line or closed valve block. Once the pressure on the compressor head reaches a certain limit, this valve will ‘pop’ off and prevent an overpressure condition.

A pressure gauge is great to monitor what your normal running pressure is at when the system is operating well. What pressure the gauge reads is a combination of the backpressure it takes to push air to the bottom of your pond and through your diffuser, along with the friction loss from the air line. In general, you will have about 0.43 PSI of pressure, per each foot of water depth. This, plus 0.5 – 2 PSI of line loss from the airline friction and diffuser backpressure will give you your total system pressure. For example, estimate on a 20’ deep pond you would have 0.43 x 20’ = 8.6PSI, plus maybe another 1PSI of line loss for a total pressure of 9.6 PSI. If your pressure gauge is running anywhere close to that, all is probably good. If it’s really low, and your air diffuser plume looks smaller in the pond, you could need a rebuild or your air filter may be plugged. If the pressure is much above where it should be, you may have a freeze-up issue, a pinched line or your valves on the manifold may be pinched back to much.

HELPFUL HINT: If you have more than one airline and diffuser running to your pond on your aeration system, you most likely have some sort of air control valves in. You should ALWAYS have at least one of the valves 100% OPEN. In general, this would be the deepest diffuser and/or the longest airline. Shorter/shallower diffusers will be the ones to pinch back slightly to force air through to the deeper ones.

Recommended Rebuild Intervals

These are estimates, rebuild intervals can vary considerably depending on the operating environment.

Generally a compressor aerating a very deep pond (35’) will require a shorter rebuild interval than the same compressor aerating a shallow pond (12’). The pond with more depth requires the compressor to work harder, operating at a higher pressure and elevated temperature to push air into deeper water. Other factors can shorten rebuild cycles would be a dusty or dirty environment, inadequate air filter maintenance, and improper cooling. Being proactive and having your compressor rebuilt on a regular schedule is the best bet to limit the risk of failure and fish kills, and to ensure you get the most life from your equipment.

Compressor Brand Rebuild Interval

-

Vertex Brookwood Piston Compressors: every 24-36 months

-

Matala Piston Compressors: Maintenance kit every every 12-24 months

-

Kasco Teich-Aire Piston Compressors: every 12-24 months

-

Gast 71R/72R Piston Compressors: every 24-36 months

-

Thomas Piston Compressors: every 24-36 months

-

Hakko Linear Air Pumps every 24-36 months

-

107DC Brushed Diaphragm Compressor (solar) every 12-18 months (including motor brushes)

-

DC102 Brushless Twin Piston Compressor (solar) every 18-36 months

-

DC101 Brushless Solar Diaphragm Compressor (solar) every 12-24 months

-

DC50 Brushless Solar Diaphragm Compressor (solar) every 12-24 months

WE SERVICE WHAT WE SELL, AND MOST OTHER STUFF TOO!

Too busy!?

We can rebuild your compressor for you, typically within a 1-2 day turnaround of dropping it off at the farm or shipping it to us. We can also send out a service technician to your location to rebuild the compressor on site. Please contact us for rates to your specific area.

Backup?

Take the panic out of worrying about rebuilds. Many of our customers have purchased a backup or secondary compressor or air pump for their aeration system. They swap in the fresh unit, and drop off or ship their worn unit in for a rebuild with ZERO downtime. It makes for less stress if you know you have a loaded pond (full of live fish for the winter) and don’t want to risk an oxygen drop

FROZEN HOSE?!

If you have been aerating your pond or lake for more than one season, there is a good chance you have run into some freeze up issues. Anytime you compress air, you will be concentrating the humidity that is present. When the humidity gets high enough, it turns from a gas to a liquid and that moisture turns into water droplets. This process is enhanced by the cold. As those water droplets make their way down the airline, they freeze and cause blockage.

In a perfect setup, any exposed airline should be insulated with foil bubble wrap, or foam pipe insulation from the compressor to the pond edge (and a few feet into the water for the best success). If you are more than 50’ of distance between the compressor and the pond, we recommend trenching the airline in and insulating to the bottom of the trench at each end. On shorter runs within 50’ that are buried, you may not need to be more than a foot or two deep. Over 50’ and we would recommend a minimum of 3ft deep, and if you are in an area with heavy traffic, this may need to be 4-6’. If you are unsure, please contact us for information. We do have insulated aeration hose if you are not wanting to have the line more than a few inches under the surface.

Some problematic scenarios would be: having excess airline coiled up on shore between the compressor cabinet and the water’s edge, having airline just lying on the surface of the ground, having the airline travel uphill over a berm or down into and out of a ditch allowing a place for moisture to collect. To help prevent freeze-up issues, always cut out excess airline, if possible run the line on a downward slope to the water’s edge, and use insulation and/or trenching to hold some of that compressor heat in the airline.

My pond freezes completely over when it’s really cold, but my compressor still runs is this normal? Yes! Ponds that are aerated 24/7 in the winter, and especially smaller shallower ones will very commonly freeze right over when the weather gets very cold (-15C or colder for extended periods). Aeration will chill the water, and shallower ponds can see the water temperature get to as cold as 0.2C so it’s very easy for ice to completely cover the pond when it gets cold. As long as your aeration system is running properly (check the pressure gauge), you don’t need to worry.

Winter Aeration Safety

Fence your pond off! Put up signs! Talk to your family, friends and neighbours about the risks. If possible we recommend fencing your pond, or at the very least fencing off the areas of ice above the diffusers. If you have kids that skate on the pond or ice fish, dogs or other pets or animals hanging around, having open water or thin ice conditions can be dangerous.

We have customers who run snow fence around the area of the pond where the diffusers are at, or some may choose to shut off one diffuser if they have more than one, and rope off the end that is still aerated. Our own trout pond here at the farm gets temporary fence put up across the end to keep our dogs out. On larger bodies of water this may mean snow fence/rope and signage to notify snowmobilers, cross country skiers etc. If your pond freezes right over, don’t try and break open the frozen area over the diffuser! The hole will open up again when the weather warms up. its extremely dangerous to try and break it open so just don’t do it!

Winter Feeding

Should I feed my fish in winter? As a general answer – No. With the low water temperature seen during our winters, fish metabolism slows down considerably, and the fish will get the small amount of nutrients they need from exiting aquatic life. That being said, if you have plenty of open water during parts of the winter and you can see the fish actively surface feeding on the pellets, you can maintain some extra weight on the fish and get a small amount of growth over the winter. Uneaten feed will add considerably to the nutrient loading in spring so if they are not eating the feed, stop tossing it in.